thermoduric bacteria

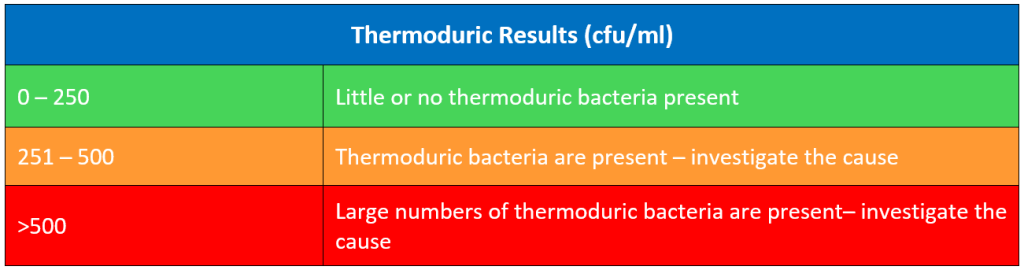

Thermoduric bacteria are heat resistant bacteria that can survive pasteurisation and grow through cheesemaking and ultimately ending up in final product. They are present in silage, faeces, soil and animal bedding, and can enter the milking equipment through dirty teats at milking time. They affect product quality and can hinder the production of ingredients for sensitive applications such as infant nutrition. Because of their ability to withstand pasteurisation temperatures, the initial numbers in milk must be low. A thermoduric level of 500 cfu/ml or less is necessary in milk to ensure that it is fully suitable for processing. The table below shows what the results of thermoduric bacteria testing means.

Source of Thermodurics:

- Thermoduric are commonly associated with some source of contamination – levels can be higher in wet or extremely dry weather.

- Commonly found in the environment, dust, in soil, airborne, bedding, faeces of cows.

- Present in deposits on milking machines and bulk tanks.

- Cracked/old rubberwear is an ideal environment for bacteria to harbour, where they are protected from hot water and chemicals.

Steps to Reduce Thermoduric Bacteria

- wash & dry cows teats to prevent thermoduric bacteria getting into the milking machine in the first place.

- keep the cow’s environment clean, dry and free from accumulations of waste silage and slurry to avoid contamination of teats and reduce bacteria levels. Maintaining roadways and gaps, as well as cleaning collecting yards, passageways and cubicles daily will also reduce bacteria.

- replace old or perished rubberwear – regular inspection of rubberwear is vital.

- check your claw pieces regularly by opening them to ensure there is no build up – this will tell you whether they are getting enough water, if the water is hot enough, and if your detergents are effective.

- check your hot water is hot enough (75 – 80 ⁰C) and of sufficient volume (9 litres min per unit) to really clean your milking equipment.

- if using a liquid detergent, use a high concentrate caustic powder once a week.

- descaling the milking machine regularly

- after you descale, rinse and then do a detergent wash immediately, to ensure no resettlement of bacterial build up.

- ensure milk is cooled to 3-4⁰C within 30 mins of milking finish.

- disinfecting the plant with peracetic acid as an additional rinse

- cleaning the vacuum lines periodically

- using a clean filter sock during washing

- inspecting the bulk tank periodically to ensure effective cleaning.

get in touch

If you need help or advice, please contact a member of the milk quality advisory team